| Al2O3 | 78-85% |

| SiO2 | 8-12% |

| Fe2O3 | 3.5% (max) |

| TiO2 | 3.5% (max) |

| Refractoriness | 1850C (3362F) |

| Angle Coefficient | 1.1 (max) |

| Thermal Expansion (at 100°C) | 0.15 |

| Thermal Conductivity | 0.196 W/m.K |

| Specific Heat | 873 J/kg |

| Bulk Density | 1.9-2.2 g/cm3 |

| pH Value | 7.65 |

| Shape | Solid Sphere |

| Binder Content Required | 3-4% |

| Crushability | 112 |

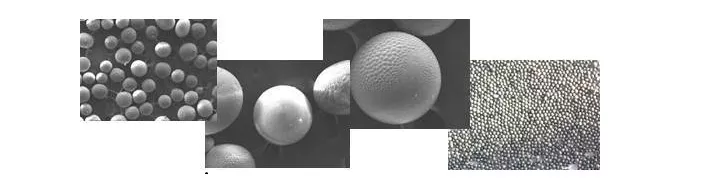

Bauxitic Casting Pearls (also called ‘Ceramsite’) are innovative spherical casting sand developed in the Far East initially for the discerning Japanese markets. With the excellent casting property feedback and lower price.

Ceramsite has already conquered the Japanese and Chinese markets, and being considered as a direct replacement for Chrome and Zircon casting grade Sands. Available in a variety of AFS sizes, The Ceramsite offers a “Chrome Free” option where environmental considerations are a real concern.

Our high quality Ceramisite sands are made by fusing, spraying, sieving and purifying high Alumina Calcined Bauxite. They can be used in casting all sizes of steel parts. The spherical shape produces high density material with excellent flow characteristics. The main chemical composition is Al2O3 which provides an excellent refractoriness and stability.

Ceramsite sand characteristics and casting benefits:

High AI2O3 mineral composition

- Higher Refractoriness than Silica based sands (around 1850 C°)

- Much lower Thermal Expansion compared to Chromite and Zircon based sands

- Reduce Burn in

- Compatible with existing resin systems

Regular spherical shape

- Provide highly smooth surface

- Reduce binder addition

- Excellent air permeability and dispensability (reduce cleaning cost)

100% recyclable

- Cost reduce (up to around 40 times against 5-10 times for chromite based sands)

- Environment respect and health safety